How Long Do Micron Rosin Bags Last?

Rosin filter bags are a necessary cost of pressing rosin and one that can add up over time. Some extractors may wonder what the shelf life of rosin bags is and whether they can be reused to reduce costs.

The short answer is that rosin bags (typically made from nylon mesh) last for years when packaged and stored appropriately. However, they are single-use items and should not be reused to press rosin from another batch of bubble hash or dried plant material.

Why You Can't Reuse Rosin Bags

You can’t reuse rosin bags because they are not designed to withstand more than one squeeze. Rosin bags are made with great care and precision to promote rosin flow while keeping unwanted plant material and trichome cuticles inside the bag. They are generally made from nylon and come in a range of dimensions and micron sizes to suit different rosin presses and starting materials (for hash rosin, flower rosin, and so on).

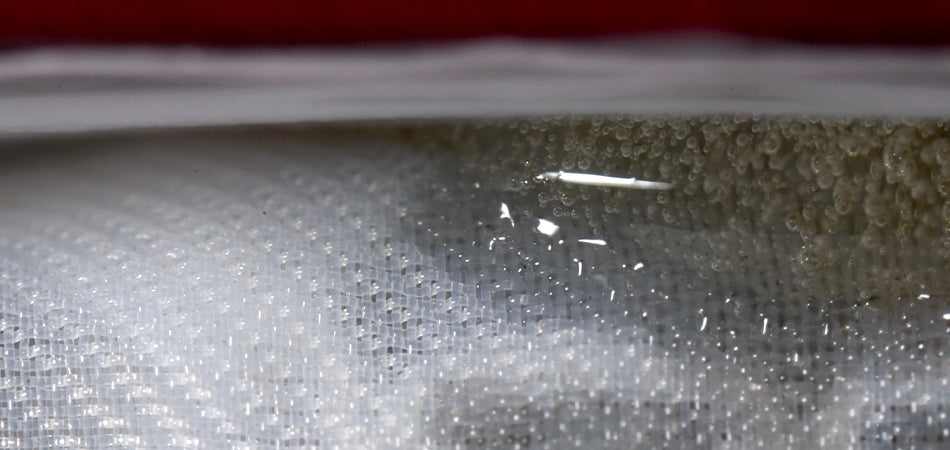

When a micron rosin bag is packed with bubble hash, dry sift, kief, or flower, placed between the heated plates of a rosin press, and squeezed under a tremendous amount of force, the nylon stretches to accommodate the pressure, and rosin flows out through the pores. The trichome cuticles, fats, waxes, lipids, and plant material remain inside the bag throughout the process, forming the "rosin chip" that is left after pressing is complete.

This stress and stretching is why we recommend double 25µm bagging your presses. Or even taking it a step further and using our Bulletproof tech by wrapping a third 220µm rosin bag around your product before the press. The rigidity of the 220µm Bulletproof rosin bag prevents extra stress and nearly eliminates the possibility of a blowout.

There are several uses for rosin chips including making cannabis salve. However, we don't recommend removing the rosin chip from the bag, cleaning the bag with rubbing alcohol (as some suggest), and using it to press new starting material. There are several important reasons for this:

Risk of Contamination

Used micron bags contaminate subsequent batches of rosin. This occurs in two key ways:

- Residual Material: After a single use, rosin bags retain residual plant matter and oils that are difficult to fully clean. This can lead to contamination in subsequent extractions, impacting the purity and taste of the final product.

- Cross-Contamination: Reusing bags across different strains or batches can lead to cross-contamination, affecting the flavor profile and quality of the rosin.

Compromised Integrity

Used micron bags are not as strong as new bags and are much more prone to blowouts.

- Weakened Seams: The seams of the rosin bags can weaken after the first use due to the pressure and heat applied. This can lead to blowouts during reuse (where the bag bursts) allowing plant material to mix with the rosin.

- Material Degradation: High heat and pressure cause the nylon fibers to stretch and weaken, reducing the bag's effectiveness in future presses.

Impact on Yield and Quality

The yield from a used rosin bag will be impacted both by stretched pores (this changes the effective micron size) and clogged pores from the previous press. This has two important consequences:

- Reduced Filtration Efficiency: The bag's ability to filter out impurities diminishes as the bag's mesh structure degrades, leading to a lower-quality final product with potentially more contaminants.

- Inconsistent Results: Reused bags can result in inconsistent rosin yields, as the bag's structural integrity is compromised. This affects the efficiency of the extraction process.

Can You Reuse Other Kinds of Rosin Bags?

Polyester, silk, and metal bags made from stainless steel for rosin pressing are also one-use products. Polyester and silk are even less resistant to blowouts than nylon mesh because they are more rigid and don’t stretch effectively under pressure. Attempting to reuse rosin bags made from either of these materials would be a recipe for disaster.

Stainless steel is strong and resistant to scaling (oxidation) at high temperatures and would be less likely to break if used a second time. However, it would still be difficult to clean a stainless steel micron screen well enough to get around the risk of cross-contamination.

Better Ways to Save Money on Rosin Bags

There are strategies to save money on rosin bags that don't jeopardize the quality of the final product:

- Purchase high-quality rosin bags that won't burst under pressure to avoid wasting bags and starting material.

- Buy rosin bags in bulk for a lower per-unit price.

- Use the right size rosin bag for your starting material and rosin press plates to avoid wasting rosin bag material with large lengths cut off after folding.

Buy the Right Rosin Bag and Use It Once

Rosin filter bags last a long time in the packet but must be discarded once they have been used. They are designed to filter cannabis resin effectively under pressure and heat only once because they become weakened and contaminated with plant material through the process.

The best ways to optimize your rosin bag costs are to choose a high-quality brand, purchase in bulk, and use the right size for your starting material and rosin press plates. While it might seem cost-effective to reuse rosin bags, the potential loss in yield and quality, along with the risk of contamination, can ultimately result in higher costs in the long run.