What Are Rosin Bags Made Of?

Rosin bags for pressing cannabis can be made from four primary materials: nylon, polyester, silk, and stainless steel. Each of these materials has its pros and cons.

The most popular material for rosin filter bags is currently nylon due to its superior performance for pressing rosin. Understanding the characteristics of nylon and the other materials used for rosin bags will help you make an informed choice for your solventless extraction operation.

Nylon Rosin Bags

Nylon is considered the best material for making rosin bags for use with a rosin press. There are several reasons for this:

- Nylon is exceptionally strong and durable. It is so strong that it was used to make parachutes in WWII.

- Nylon has greater elasticity than polyester and raw silk. This means it stretches rather than breaking when filled to maximum capacity and placed under pressure.

- Nylon has a high boiling point of 430ºF (220ºC), depending on which type of nylon is used. Rosin extractors generally press at 180ºF to 240ºF at most. Some folks may press at up to 300ºF (we don't recommend this) and even then won't reach nylon's boiling point.

- The FDA has developed a specific regulation for nylon resins used to process, handle, or package food (FDA Code of Federal Regulations (Title 21: Nylon resins). Reputable rosin bag manufacturers take care to follow this regulation. Our rosin bags are both food-grade and dye-free for your safety and peace of mind.

Rosin Filtration Bags Made from Other Materials

You will also find rosin filtration bags made from polyester, raw silk, and stainless steel.

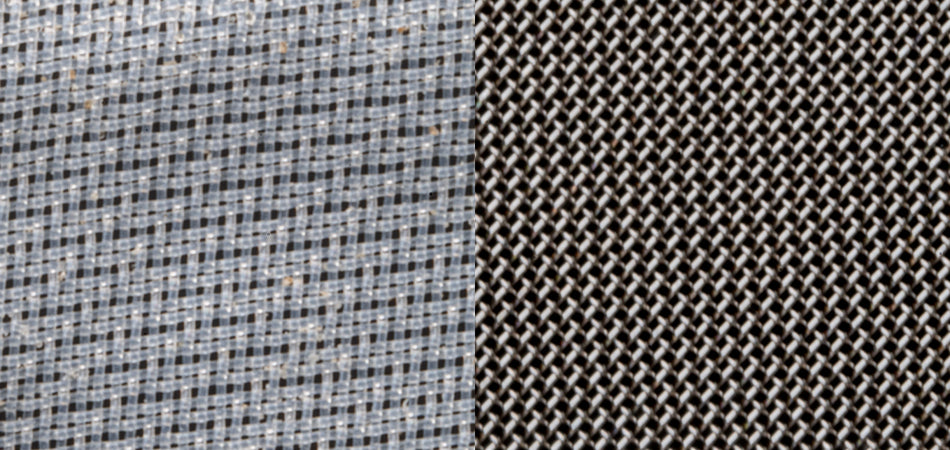

Polyester Rosin Bags

Polyester has been used successfully to make rosin bags. The main advantage of this material is that it has a lower cost than nylon. It also maintains its micron rating better than nylon because it is more rigid (as opposed to elastic).

Polyester comes with a few downsides, however:

- Polyester has less elasticity than nylon. This makes it more susceptible to blowouts.

- Polyester shrinks with heat.

- Polyester is not as durable as nylon.

Silk Rosin Bags

Raw silk can be used to make rosin filtration bags that are natural and non-toxic. This material, however, is not common in rosin pressing for the following two reasons:

- Silk costs 10-15 times more than nylon.

- Silk does not have much elasticity and is thus more prone to blowouts.

Please note: Some rosin bags are marketed as “silk” or “silk screen” but are actually made from nylon. Check the product specifications carefully before presuming that a “silk” rosin bag is made from natural silk.

Stainless Steel Rosin Bags

Metal bags made from stainless steel are another option for pressing rosin. The filaments are very fine to achieve the micron distances required across each filtration hole.

The advantages of stainless steel are that it is food-grade, very strong, and can withstand very high temperatures. The primary disadvantages are that stainless steel rosin bags tend to produce a lower yield and can damage the plates when pressure is applied in the rosin extraction process.

Additional Considerations When Buying Rosin Bags

We've established food-grade nylon as the best material for a rosin micron bag. However, you will also need to take dimensions and micron sizes into account when deciding which rosin bags to purchase.

Rosin Bag Dimensions

Rosin bags come in a range of sizes for different uses and to fit on specific rosin press models. For example, our 25µm/160µm rosin bags come in 2.9" x 6" and 1.9" x 4" options to fit the platen sizes of the Lowtemp V2 Rosin Press 4x7 and Lowtemp V2 Rosin Press 3x5.

You want a size that leaves one inch of space on all sides of the bag once the end has been folded over. You can use a pre-press mold to shape the (bagged or unbagged) plant material to the exact size of each of our rosin presses and remove air pockets for greater efficiency when pressing rosin.

Micron Sizes

The micron size is also essential to take into account when deciding which rosin bags to buy. We recommend our 25µm rosin bags for pressing bubble hash, dry sift, and kief, and our 160µm bags for pressing flower and trim. We find that these micron sizes result in the best yield and quality.

Stitching and Seams

The way the rosin bag seams are finished is the last detail to take into account. Double-stitched seams (such as those used in our Platinum Stitch Hash Rosin Pouches) are strong and very resistant to blowouts. Our Bulletproof 220u Stitchless Rosin Pouches are welded at the seams rather than stitched for superior strength.

Succeed with the Right Rosin Bags

Dye-free, food-grade nylon rosin bags with double-stitched or welded seams will give you the most reliable results with great yields, a safe end product, and zero damage to your rosin press. While there are other kinds of rosin bags out there, they don't live up to nylon in our experience.

It's essential to consider the dimensions, micron, and stitching techniques used as well as the material when selecting rosin bags for your extraction operation. When you have the right rosin bags and see that they do their job right every time, you can focus on creating high-quality solventless products with full peace of mind.